Global Plastics and Rubber Innovation Takes Center Stage in Shanghai with Five Reasons to Attend the 2026 Edition

Following an impressive closing in Shenzhen this April, CHINAPLAS 2026 will be held at the National Exhibition and Convention Center (NECC), Hongqiao, Shanghai, PR China from April 21 to 24, 2026. This premier plastics and rubber trade fair is expected to attract 4,600+ prominent exhibitors from around the world, showcasing cutting-edge technologies and innovative solutions in the vast exhibition halls of over 390,000 square meters. All industry professionals are welcome to delve into this annual trade show with infinite business opportunities.

Held alternatively between Shanghai (even years) and Shenzhen (odd years) and focusing on the theme of “Transformation · Collaboration · Sustainability”, CHINAPLAS will bring the latest transformative trends plus pulse of development in plastics and rubber industries, acting as a pioneer with forward-looking vision. With its exceptional value in providing business and networking opportunities for exploration, here are 5 reasons why you shouldn’t miss this world’s leading plastics and rubber trade fair.

Held alternatively between Shanghai (even years) and Shenzhen (odd years) and focusing on the theme of “Transformation · Collaboration · Sustainability”, CHINAPLAS will bring the latest transformative trends plus pulse of development in plastics and rubber industries, acting as a pioneer with forward-looking vision. With its exceptional value in providing business and networking opportunities for exploration, here are 5 reasons why you shouldn’t miss this world’s leading plastics and rubber trade fair.

Leading Industry Development as the Barometer

In 2026, CHINAPLAS will embark on a new journey toward its 38th edition. As the gateway for release and exchange of advanced technologies covering the entire plastics and rubber industry chain, the trade fair will bring together the industries’ top enterprises in the world, while showcasing a wealth of new and emerging technologies. Thousands of machines will be on display for live demonstrations, offering an impressive showcase of plastics and rubber innovations. Additionally, a variety of concurrent activities are planned to gather industry leaders and experts for discussion on latest technologies, design and innovation, cost efficiency optimization, new applications, industry policies, etc., providing all-round insights and opportunities for networking. This 4-day premier plastics and rubber trade fair serves as an exceptional and indispensable platform for accessing comprehensive solutions, obtaining first-hand market information, connecting with international resources, broadening global perspectives, deepening supply chain collaboration and grasping the pulse of industry development.

Empowering Quality Progression with Innovative Solutions to Intensive Competition

Empowering Quality Progression with Innovative Solutions to Intensive Competition

Over the past year, in view of China’s intensive competition and price wars within various industries, plenty regulations have been implemented to curb such trend, including optimization of industrial layout, address of disorderly low-price competition and enhancement of product quality. The shift from competition in price to technologies, and from price to value, underscores that technological innovation is the essential driving force in breaking through this “intensive competition”. The technology-driven CHINAPLAS 2026 aims to build a hub for plastics and rubber innovation, where global suppliers will assemble to showcase thousands of machine exhibits, as well as inventive solutions from over a thousand of raw material suppliers. These pioneering technologies will serve as solid technical foundations for downstream application industries, such as automotive, electronics & electric, packaging, medical & healthcare, building & infrastructure, etc., to address the needs for transformation and upgrading, as well as enhance product competitiveness. Such empowerment will enable the plastics and rubber industries to overcome homogeneous competition and focus on the journey toward high-quality growth.

Unlocking Trillion-Dollar Opportunities by Focusing on Emerging Sectors

Unlocking Trillion-Dollar Opportunities by Focusing on Emerging Sectors

Exploring new fields and incremental markets is as crucial as breaking free from intensive competition. CHINAPLAS 2026 will center on multiple emerging sectors with rapid development – low-altitude economy, in particular new-generation aircraft represented by eVTOLs, is poised to become a trillion-dollar industry with immense growth potential. Shanghai, at the forefront of China’s economy, is striving toward the goal of becoming the capital of low-altitude economy with plans to achieve an industry scale of over RMB 50 billion by 2027. Currently, China’s robotics industry has established itself in the leading position among the global leaders. According to Goldman Sachs’ forecasts, the global market size for humanoid robots is expected to reach USD 38 billion by 2035. Over the next decade, this will become another trillion-dollar sector following the new energy vehicle industry. Meanwhile, explosion of the “Guzi” economy (derived from homonym for the English word “goods”, it refers to the economic activities centered around spin-off products of ACGN – animation/ comics/ games/ novels) in China has fostered evolution of the art toy industry. Data from media Research indicates that in 2024 China’s pan-ACGN users has surged to 503 million, and the market scale is expected to expand from RMB 597.7 billion in 2024 to RMB 834.4 billion by 2029. Additionally, rapid advancements in human spaceflight, large aircraft, high-speed rail, smart driving, high-end medical technology, e-commerce, and food delivery packaging have led to higher demands on plastic raw materials and forming processes, while also creating significant business opportunities.

Green Technology and Intelligent Solutions Reshape Future of Plastics and Rubber Industries

Green Technology and Intelligent Solutions Reshape Future of Plastics and Rubber Industries

Green technology and intelligent solutions have become the main themes of plastics and rubber industries’ development, with green and low-carbon initiatives driving transformation, and intelligent and efficient technologies shaping the future. To align with the trend of circular economy and meet industry demands, CHINAPLAS 2026 has established 3 related theme zones: Recycled Plastics Zone, Bioplastics Zone and Recycling Tech Zone, showcasing advanced green and low-carbon technologies. In the Chemicals & Raw Materials Zone, well-known exhibitors will introduce innovative sustainable solutions. With smart manufacturing being the future trend for plastics and rubber industries, the combination of digital production and artificial intelligence (AI) will further accelerate the industries’ upgrade and transformation, as well as trace the path of plastics at different stages of the circular economy, achieving a comprehensive closed-loop ecosystem. Besides, AI can assist enterprises to achieve dual improvements in production efficiency and precision through process innovation, and maintain a competitive edge in the progressively digitalized development landscape. CHINAPLAS 2026 is committed to promoting the high-end, green, and intelligent development of the plastics and rubber industries, reshaping their future.

Fully Tapping into International Markets, with Global Business Opportunities within Reach

Fully Tapping into International Markets, with Global Business Opportunities within Reach

CHINAPLAS has deeply rooted itself in China’s plastics and rubber market, serving as an outlet for development opportunities not only in Asia, but also the world. The trade fair in 2025 attracted 281,206 professionals from over 170 countries and regions worldwide, with 68,542 visitors (24.37%) from overseas and Hong Kong, Macau and Taiwan region of China, marking a new leap in internationalization. Exhibitors successfully pursued the networking and trade opportunities further by forming strategic partnerships and signing deals with local and international buyers, demonstrating the exhibition’s exceptional ability in converting trade opportunities to tangible results. Along with the kick start of CHINAPLAS 2026 promotion to global buyers, a series of projects have been planned – visiting industry chambers of commerce, associations and buyers in different countries and regions, participating in key industry events as well as running targeted promotional campaigns, in order to reach global buyers and discover golden opportunities.

With booth spaces highly sought-after by the industry, CHINAPLAS 2026 will strive to present an annual global event of professional excellence, plentiful innovative achievements, and significant commercial value, helping enterprises seize market opportunities. From exhibitors and products, creative technologies and solutions, fruitful concurrent activities to on-site services, the exhibition will bring spectacular experience and value to all participants for sure. CHINAPLAS held in Shanghai, April 2026 is definitely a trade show you should not miss!

www.ChinaplasOnline.com

#CHINAPLAS2026 #Modernplasticsindia #Pasticsnews #ModernPlasticsIndiaMagazine

#PrintPublication #Modernplasticsindia.in

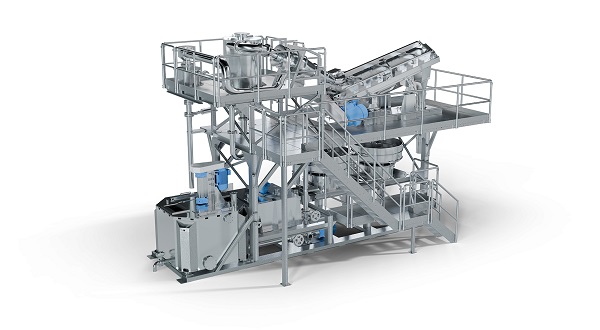

Under the banner “One conductor. One perfectly executed line,” Sidel invites visitors to Stand E52 at NEC Birmingham to explore how precision engineering, targeted upgrades, and local expertise combine to optimise equipment and packaging performance – whether manufacturers are starting a project from scratch or enhancing an existing line.

Under the banner “One conductor. One perfectly executed line,” Sidel invites visitors to Stand E52 at NEC Birmingham to explore how precision engineering, targeted upgrades, and local expertise combine to optimise equipment and packaging performance – whether manufacturers are starting a project from scratch or enhancing an existing line. Spotlights at the booth:

Spotlights at the booth:

Held alternatively between Shanghai (even years) and Shenzhen (odd years) and focusing on the theme of “Transformation · Collaboration ·

Held alternatively between Shanghai (even years) and Shenzhen (odd years) and focusing on the theme of “Transformation · Collaboration ·  Empowering Quality Progression with Innovative Solutions to Intensive Competition

Empowering Quality Progression with Innovative Solutions to Intensive Competition Unlocking Trillion-Dollar Opportunities by Focusing on Emerging Sectors

Unlocking Trillion-Dollar Opportunities by Focusing on Emerging Sectors Green Technology and Intelligent Solutions Reshape Future of Plastics and Rubber Industries

Green Technology and Intelligent Solutions Reshape Future of Plastics and Rubber Industries Fully Tapping into International Markets, with Global Business Opportunities within Reach

Fully Tapping into International Markets, with Global Business Opportunities within Reach